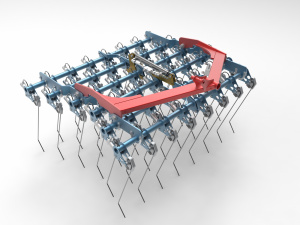

"Original Harrow" Air-Flow

The brightest star in the harrow sky

- New patented harrow tine spring system

- Can be used in almost all the crops

- The tines is proviede by a pneumatic cylinder

New presentation: HATZENBICHLER Air-Flow

Patented harrow tine spring system.

The only manufacturer that has been producing the original harrow for well over half a century is introducing a completely new patented harrow tine spring system in time for the 2020 season.

The engineers at Hatzenbichler developed a system with which it is possible to continuously adjust the tine pressure at a constant tine angle

The Air-Flow harrow

The spring action of the tines is provided by a pneumatic cylinder with a spring travel of only 30 mm, which enables a 45° spring path of the tines.

The central air supply is provided by the compressed air brake system of the tractor. A proportional pressure regulator enables the cylinder to be pre-tensioned in the 1/10 bar range up to a maximum of 6.0 bar.

In this way, the tine pressure can be infinitely adjusted from 500.00 – 5000.00 g. Uniform cultivation of ridge crops and uneven soil conditions is thus guaranteed.

In contrast to the tension springs pre-tensioned with wire ropes, the new Hatzenbichler harrow features actual constant tine pressure.

The tine aggressiveness

In addition, the tine angle and thus also the tine aggressiveness can be adjusted within the range of 55° – 128°.

As far as is known, this is not possible with any other manufacturer. Due to the wide bearing of the tine holder, the lateral deflection of the tine is minimized. A passage height of 590 mm allows the harrowing of higher crops.

The 1.5 m field and a tine spacing of 25 mm ensure optimal ground hugging.

Since the new harrow arrays including pneumatic equipment can be mounted in the Hatzenbichler harrow frames, which have been tried and tested for decades.

Monitor Overview:

8,4" Touch Display

5,6" Touch Display with Softkeys

5" Touch Display with Softkeys

New Supplementary Locator Technology

Hatzenbichler has expanded its system for optimal harrow applications with the Locator Technology. It is now possible to adjust the tine pressure of each individual harrow tine separately via a terminal from the tractor cabin.

What can the Air-Flow powered by Locator do?

Each tine can be switched between two continuously adjustable pressures. On the plant row, low tine pressure, whereas high tine pressure is applied between the plant rows.

The row spacings can be freely selected on the terminal while driving. Also, the bandwidth is freely adjustable via the terminal during the drive.

Using the virtual steering frame, the offset is continuously adjusted by Locator row recognition.

Now it is possible to harrow earlier in the cotyledon stage. But also in later cultures, where, for example, other harrows could "injure" the tall crop plant.

Higher working speed allows for greater area performance.

Savings in hoeing passes or even complete avoidance of hoeing passes.

What can the Locator do that other plant recognition systems cannot?

- Better visual plant recognition by human and AI

- Continuous training of the AI by the human

- Unlimited computing power possible through outsourcing to data centers

Benefits

We develop and build our products with the daily experiences of our customers in St. Andrä in Lavanttal Austria - the best engineering and highest manufacturing quality meet perfect spare parts supply. Our machines are for professionals - day after day!

The Hatzenbichler "Original harrow" Air-Flow

The new harrow tine spring system

The best alternative to the chemical weed control

Video

The Hatzenbichler "Original harrow" in use

"Original Harrow" Air-Flow

Technical details

Equipment

- 3-point hitch

- With pneumatic cylinder with central air supply of the tractor

- Hydraulically foldable

- Height-adjustable support wheels on ball bearings

- Tine width 7mm, tine length 450mm

- Transport lock - through valve

- Automatic transport lock mechanism - operation from the tractor seat

- Transport width 3m

Special equipment

- Backpack Controller (ISOBUS-control)

- Monitors with 8,4", 5,6" and 5" display

-

Holder with track eradicator tine

- Stepless height-adjustable spindle adjustment on the support wheels

3-point hitch rigid

| working width | fields | tine diameter | wheels | weight in kilograms | kW | HP |

|---|---|---|---|---|---|---|

| 1,5 m | 1x1,5 m | 7mm | 2 | 240-260 | 9 | 13 |

| 3,0 m | 2x1,5 m | 7 mm | 2 | 390-410 | 18 | 25 |

Hydraulic foldable

| working width | fields | tine diameter | wheels | weight in kilograms | kW | HP |

|---|---|---|---|---|---|---|

| 4,5m | 3x1,5m | 7 mm | 2 | 580-620 | 18 | 25 |

| 6,0m | 4x1,5m | 7 mm | 2 | 730-770 | 37 | 50 |

| 7,5m | 5x1,5m | 7 mm | 4 | 1.000-1.060 | 44 | 60 |

| 9,0m | 6x1,5m | 7 mm | 4 | 1.180-1.260 | 60 | 80 |

| 9,0m* | 6x1,5m | 7 mm | 4 | 1.460-1.550 | 60 | 80 |

| 10,5m* | 7x1,5m | 7 mm | 4 | 1.630-1.730 | 74 | 100 |

| 12,0m* | 8x1,5m | 7 mm | 4 | 1.780-1.900 | 74 | 100 |

| 13,5m* | 9x1,5m | 7 mm | 4 | 1.980-2.100 | 74 | 100 |

| 15,0m*^ | 10x1,5m | 7 mm | 4 | 2.490-2.650 | 110 | 150 |

* machine crop folded

^ more than 3m transport height